#Cad cam meaning how to#

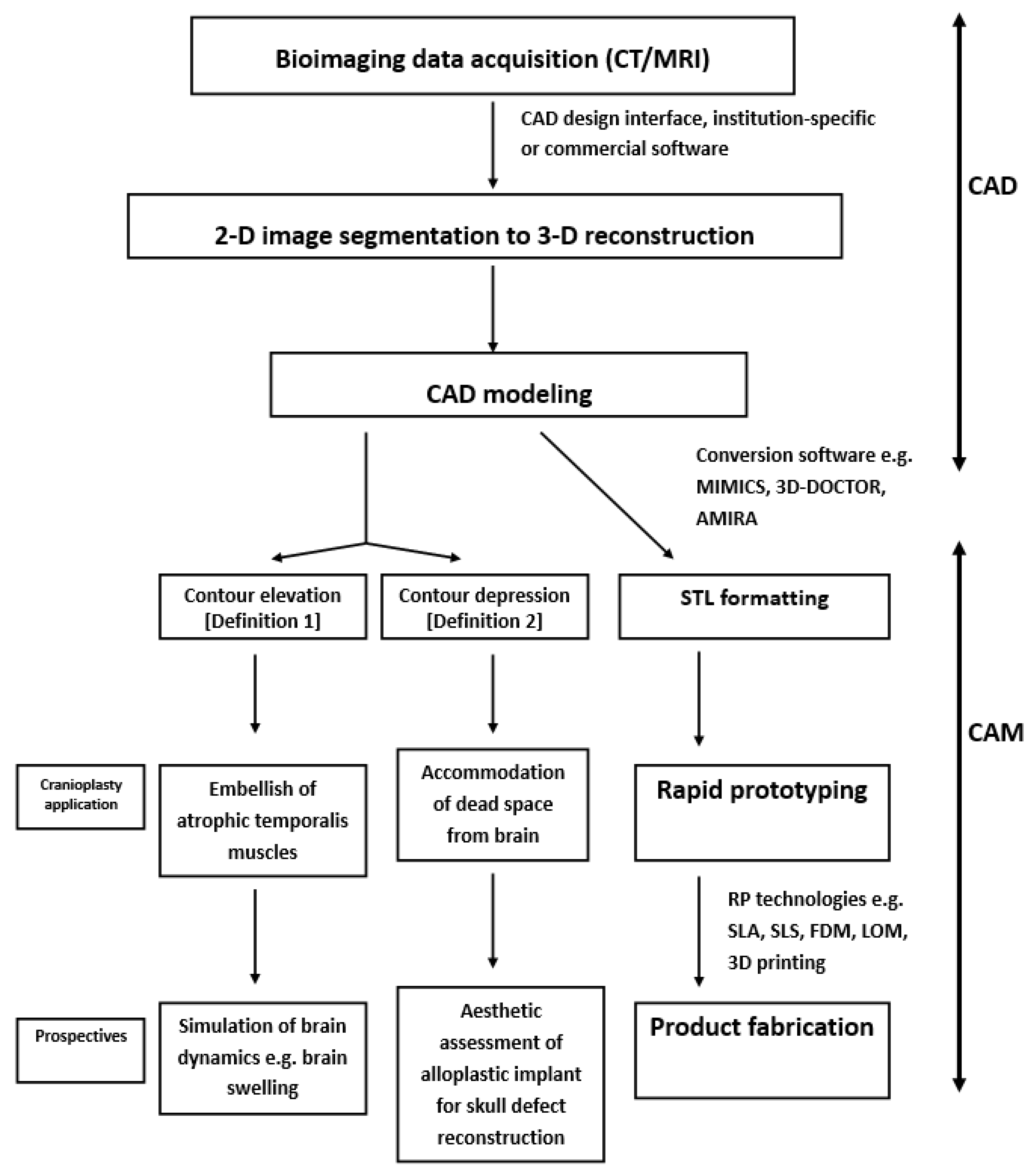

Software that tells a machine how to make a product by generating toolpaths.What is CAM? Computer Aided Manufacturing (CAM) is the use of software and computer-controlled machinery to automate a manufacturing process.īased on that definition, you need three components for a CAM system to function: What happens behind the scenes? Keep reading, and you’ll find out.

When you need something made, not just designed, CAM is your answer. We’re the ones that give the power of flight to airplanes or the rumble of horsepower to automobiles.

#Cad cam meaning full#

In a world full of physical stuff – whether that’s products, parts, or places – Computer Aided Manufacturing (CAM) makes it all possible. Such futuristic concepts, however, are all highly dependent on our abilities to analyze human decision processes and to translate these into mechanical equivalents if possible.10 min read Computer Aided Manufacturing (CAM): The Complete Introduction for the Beginner’s Mind Expert systems might also come to change the way data are stored and retrieved in CAD/CAM systems, supplanting the hierarchical system with one that offers greater flexibility. Expert systems might involve the implementation of more abstract principles, such as the nature of gravity and friction, or the function and relation of commonly used parts, such as levers or nuts and bolts. The system could then mimic the engineer's thought pattern and actually "create" more of the design. By including this and other information, the CAD system could then "know" what an expert engineer knows when that engineer creates a design. One example of an expert system involves incorporating information about the nature of materials-their weight, tensile strength, flexibility, and so on-into CAD software. This field is derived from research done in AI. Other limitations to CAD are being addressed by research and development in the field of expert systems. One of the most important trends in CAD/CAM technologies is the ever-tighter integration between the design and manufacturing stages of CAD/CAM-based production processes.

It was this source that resulted in the linkage between CAD and CAM. The third source of CAD development resulted from efforts to facilitate the flow from the design process to the manufacturing process using numerical control (NC) technologies, which enjoyed widespread use in many applications by the mid-1960s. The use of computer modeling to test products was pioneered by high-tech industries like aerospace and semiconductors. The second source of CAD was in the testing of designs by simulation. One of the important time-saving advantages of computer modeling over traditional drafting methods is that the former can be quickly corrected or manipulated by changing a model's parameters. These developments were pioneered by the General Motors Research Laboratories in the early 1960s. The first source of CAD resulted from attempts to automate the drafting process.

CAD had its origins in three separate sources, which also serve to highlight the basic operations that CAD systems provide.

0 kommentar(er)

0 kommentar(er)